Straight Weld Polyurethane/Polyamide Composite Enameled Wire

Straight Weld Polyurethane/Polyamide Composite Enameled Wire

- Detail

- Parameters

Straight Weld Polyurethane/Polyamide Composite Enameled Wire

(Super thick paint film products QPN 155/180/200)

Product Features

Ø Insulation type: Straight-weld polyurethane/polyamide composite enamelled round copper wire;

Ø Heat resistance grade: it can be made up of 155 grade, 180 grade and 200 grade.

Ø Film thickness: thick/super thick paint film;

Ø Specifications range: 0.050mm~0.600mm

Ø Performance characteristics: It can better meet the requirements of customers on high-speed/automatic winding machines. This product has excellent wear resistance and entanglement, so that after

Application Fields

Ø Due to the excellent processing suitability, this product is widely used in the following areas:

Network Transformer/Ethernet Filter

Broadband products (xDSL transformers, switches, and routers)

Connector

10G network transformer/filter

Main characteristics

Ø Insulation high breakdown voltage: >6KV;

Ø Excellent performance of tin solder: 390℃, 2s;

Ø High temperature for softening resistance: 250℃, no breakdown for 2 minutes;

Through the reflow ovens (the peak of temperature is 260℃), and the paint film does not crack;

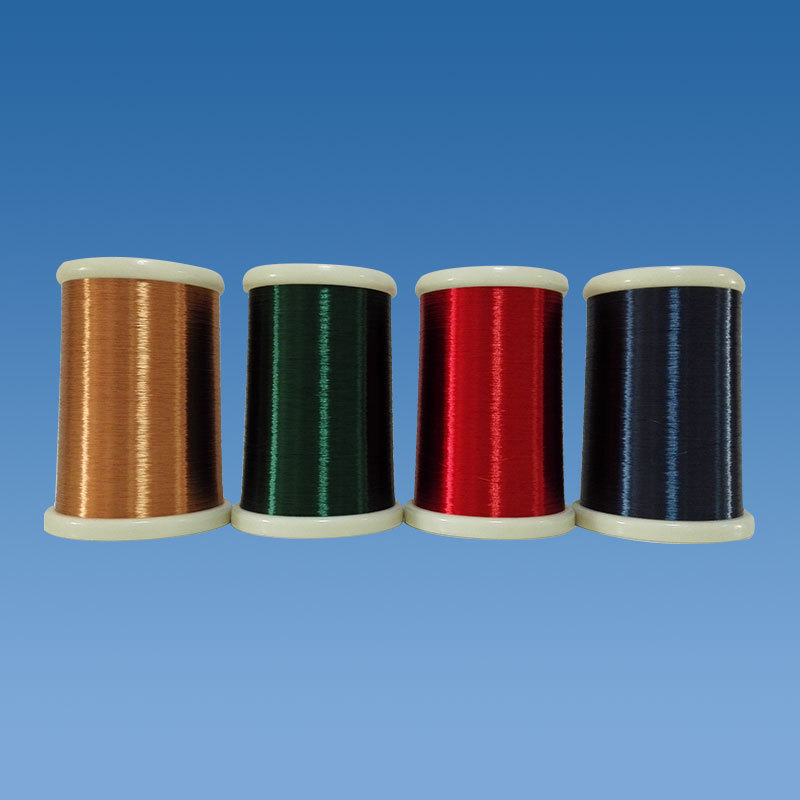

Ø Customizable colors: Natural (N)/ Red (R)/Green (G)/Blue (B);

Ø Suitable for high speed automatic winding machine to improve efficiency;

Main Technical Parameters